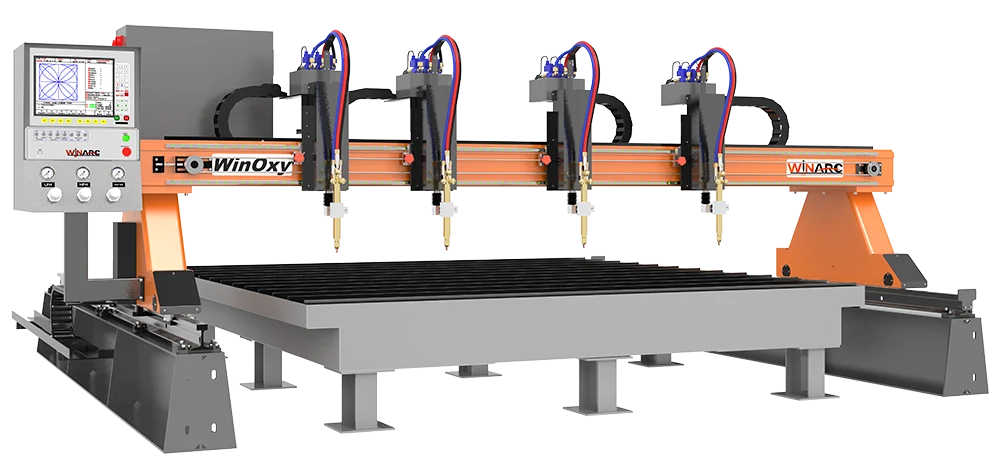

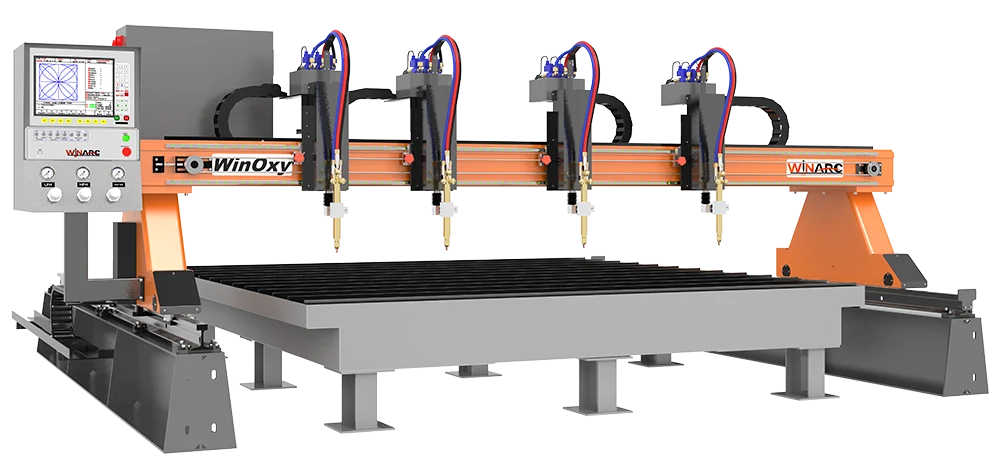

Winoxy

CNC Oxyfuel cutting machine

oxy fuel cutting machine manufactures in Bangalore

oxy fuel cutting machine manufactures

Machine with

Endless Possibilities

Winarc Oxyfuel Cutting Machine

This oxyfuel cutting machine offers a robust cutting range from 6mm to 350mm thickness, making it suitable for a wide variety of applications. As oxyfuel cutting machine manufacturers, we designed it to be user-friendly. It features an intuitive interface that simplifies operation for both experienced and novice users. Additionally, its low-cost operational features help you maximize efficiency while minimizing expenses, making it a smart investment for your fabrication needs.

KEY FEATURES

-

Sturdy machine design

Built with high-quality materials, the WinOxy is designed for durability and stability, ensuring consistent performance even under heavy workloads. -

Smooth & precise motion

Gantry topped on machined railway rails, spur rack & pinion mechanism secures precise machine movement powered by dual synchronized servo motors in longitudinal axis. Two linear guides mounted on gantry, spur rack & pinion mechanism secures precise machine movement powered by servo motor in horizontal axis. - Automatic height controller

- Capable of handling MS with thickness ranging from 6mm to 380mm

- Flexible installation options with capability to accommodate between 1 to 8 torches

-

Ergonomic operator seat mounted on gantry to reduce fatigue during long operation hours

-

Safety Features

Easily accessible emergency stop button for immediate shutdown and robust machine guards that prevent accidental contact with hazardous components. -

Customization Options

Tailored configurations are available to meet specific production needs, including different laser power options and cutting bed sizes. -

Technical Support and Service

Comprehensive support, online diagnosis and maintenance services are provided, ensuring optimal machine performance and minimal downtime.

Top Quality Brand

Components

The WinOxy oxyfuel cutting machine developed by us – experienced oxyfuel cutting machine manufacturers – is built with premium components from leading brands, ensuring reliability, precision, and longevity in industrial applications. Some of the key components are:

Linear Guides and Bearings

Brand: Hiwin or CPC

High-quality linear guides ensure smooth and accurate movement, contributing to the machine’s overall precision and performance.

Servo Motors & Drives

Brand: Delta/ Fuji

These high-performance servo motors offer rapid response times and precise control, ensuring efficient cutting and positioning.

Oxyfuel torch

Brand: Harris (Lincoln electric)

Silver-brazed twin inner tube construction type torch (capable of cutting upto 380mm) for strength & to provide optimum flow performance.

TECHNICAL Specification

CNC Oxyfuel cutting machine

- Effective length of working area

- Effective width of working area

- Max. axis speeds

- Positional accuracy

- 3000 to 30000mm

- 1500 to 6000mm

- 12000mm/min

- ±0.3mm

CAD-CAM Software:

Hypertherm Pronest, Sigmanest

- Effective length of working area

- Effective width of working area

- Max. axis speeds

- Positional accuracy

- Servo motors, drives

- X axis linear motion guides

- 3000 to 30000mm

- 1500 to 4000mm

- 12000m/min

- ±0.3mm

- Delta / Fuji

- Hiwin Taiwan / CPC 20CC LM Guide

Oxyfuel torch

Harris (Lincoln Electric)

CAD-CAM Software:

Hypertherm Pronest, Most-2d, Sigmanest

Winarc promise

Seamless and Convenient Service

We offer uncomplicated services with clear communication and execution. Take up our expert consultation online or in person, and make hassle-free purchases.

Exceptional Customer Support

We offer dedicated support throughout your entire journey. Our team is always available to help you, from problem resolution to technical assistance.

Long-Term

Partnership

We aim to be a long-term partner, continuing to support you with upgrades, maintenance, and solutions to keep your production process running smoothly.