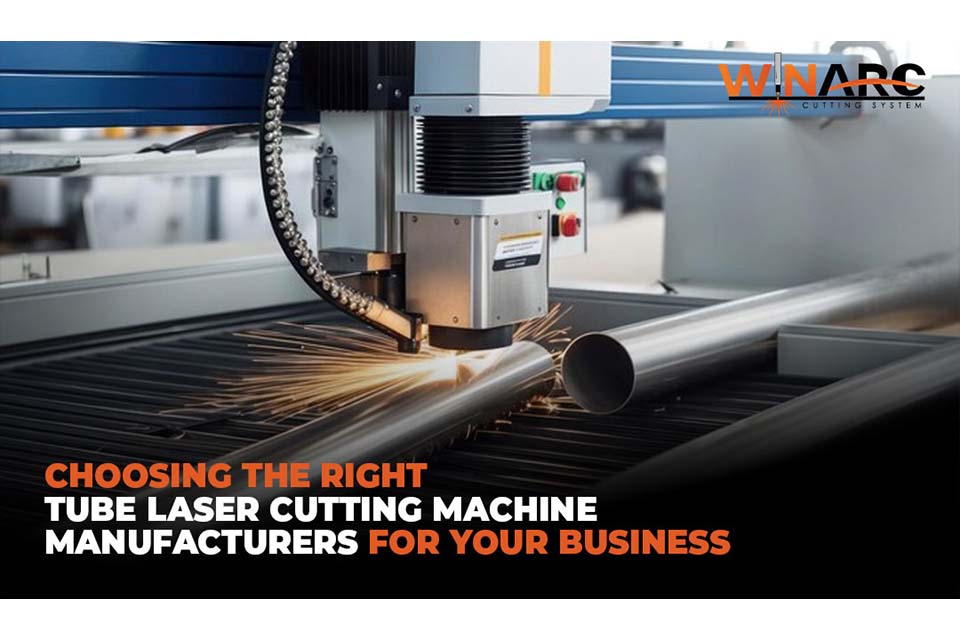

The right choice Tube Laser Cutting Machine Manufacturers has the potential to either enhance or cripple your production line. Any business in today’s market of laser cutting machines needs every possible advantage because competition in met fabricating is reaching a new peak of precision and efficiency.

Factors Relevant To Consider While Evaluating Tube Laser Cutting Machine Manufacturers

Exceptional quality, reliability and service are a must checklist when you are looking into Tube Laser Cutting Machine Manufacturers for your business. Here are the essential considerations that should be factored in before you make the final choice:

1. Accuracy And Cutting Speed

Without a doubt one of the best criteria is to excel in the execution, accuracy and speed. Machines like WinTube offers excellent functionality with cutting precision and speed with an accuracy detailed for designs and sharp finishes. The fiber laser sources increase productivity and make your operations cost effective.

2. Material Versatility

Trusted Tube Laser Cutting Machine Manufacturers like Winarc come up with designs that are made to cut a variety of materials from steel, aluminium, copper and more. WinTube is an added advantage for your production since it is compatible with steel, aluminum and copper. Not only do they cut alloys but also opens up more opportunities meeting the needs of multiple industries without needing multiple machines.

3. Durability and Quality of Construction

High-quality components and materials are used by leading Top Tube Laser Cutting Machine manufacturers. The WinTube is constructed from heavy-duty materials and high-quality components from leading brands like Yaskawa (servo motors), Hiwin/CPC (linear guides), and Precitec or Raytools (cutting heads). Not only does this ensure longer lifespan, but also reduces the chances of breakdown while working on high-demand projects.

4. Personalization and Adaptability

For your business to run smoothly you should have equipment that meets your requirements. WinTube offers different chuck size options (from ø160 mm to ø500 mm) and various laser power settings (2kW to 6kW) as well as cutting bed sizes. Both small batch and high volume production are feasible with the provided functionality of fly cut and electro-pneumatic chuck clamping.

5. User Experience and Software

Machinery should not only be powerful but also user friendly. WinTube’s system is routinely updated and, along with CAD-CAM software like Tubest Pro, ensures flow of new updates.

6. Safety and Energy Conservation

Top Tube Laser Cutting Machine manufacturers keep safety and energy consumption a high priority. WinTube’s energy efficient design reduces waste that compromises safety and cleanliness in the workspace. Features like targeted fume extraction, emergency stop systems, and durable guards around the machine all make a considerable impact during routine use.

7. Assistance and After Partnership

Trusted Tube Laser Cutting Machine manufacturers offer ongoing technical support, online diagnostics, and scheduled maintenance. For instance, Winarc focuses on making their services as stress free as possible, offering expert consultations.

Picking the Correct Choice

Make your business beneficial with a high-capacity product with the correct Tube Laser Cutting Machine Manufacturers. Winarc provides solid back-up service, flexibility, and long-term utility. When selecting your options, depend on accuracy, top quality, versatility, and after-purchase support with Winarc WinTube.

If you’re in the market for a machine that checks all these boxes, the WinTube is a strong contender worth serious consideration. It’s more than a machine; it’s a tool for forward-thinking manufacturers.

Interested in exploring the WinTube further? Reach out for a consultation or demo to see how it can transform your production line.